Custom Metal Signs – How to Customize Yours

Are you looking for resistant, well-designed, and unique signs that can transmit your business’s message? Look no further! With custom metal signs, you can have all of this. Metal is an affordable and dependable solution that can be placed in both inside and outside environments. It is also weather-resistant and low-maintenance. Metal can give your business a more distinctive and classic look. And we can help you with that! It is possible to engrave designs and even have a three-dimensional look at some materials with laser cutting. The laser-cut technology allows for designs like individual letters and flat-panel cutouts. In addition, lasers can engrave metal without altering the substrate and pick up subtle details in a project. So, if you want high-quality, custom metal signs, be sure to keep reading the article!

Aluminum vs Steel:

Aluminum and steel, two prevalent metals in industrial applications, share several similarities in terms of machinability, strength, versatility, and recyclability. Both materials lend themselves well to precision cutting and bending processes, facilitated by modern technologies like CNC machining. Their strength makes them suitable for structural applications, and their recyclability aligns with sustainable manufacturing practices. However, key differences distinguish these metals, impacting their suitability for specific applications. The density of steel surpasses that of aluminum, affecting the weight of materials and making aluminum preferable in weight-sensitive applications like aerospace.

Additionally, aluminum naturally forms a protective oxide layer, providing superior corrosion resistance compared to steel, which is susceptible to corrosion and often requires coatings. Aluminum’s greater formability, higher strength-to-weight ratio, and superior heat conductivity further contribute to its preference in certain applications. While steel is generally less expensive, the choice between aluminum and steel depends on project-specific requirements, considering factors such as weight, corrosion resistance, heat conductivity, and cost. Manufacturers carefully evaluate these factors to determine the most suitable material for their intended application.

Aluminum and steel, both widely utilized metals across diverse industries, share fundamental similarities while presenting distinct characteristics, particularly in bending and cutting processes. Their machinability stands out as a common trait, as both metals lend themselves well to precision cutting and bending techniques, facilitated by advanced technologies such as CNC machining. Moreover, their strength is a shared attribute, rendering them suitable for a range of structural applications where durability is paramount.

Talk with one of our Team about Your Project – There might be something cool we can do that you never thought of!

Versatility is another common ground for aluminum and steel. Both metals find applications in construction, automotive, aerospace, and various other industries due to their adaptability to different manufacturing processes and end-use requirements. Their versatility extends to the realm of recyclability, contributing to sustainable practices in manufacturing. The recyclability of aluminum and steel reduces the environmental impact associated with the production of new metals, aligning with the growing emphasis on eco-friendly processes.

Payment Versatility

However, pivotal differences distinguish these metals, influencing their appropriateness for specific applications. The density contrast between aluminum and steel is noteworthy. Steel, being significantly denser, contributes to a higher overall weight, making aluminum the preferred choice in situations where weight is a critical factor, such as in the design and manufacturing of aircraft components. Corrosion resistance is another area of disparity. Aluminum, by nature, forms a protective oxide layer, imparting excellent corrosion resistance. In contrast, steel is more susceptible to corrosion, especially in harsh environments. To mitigate this, various protective coatings or treatments, like galvanization, are commonly applied to steel.

Cutting, shaping, engraving – forging metal dreams into reality.

The formability of these metals diverges, with aluminum being more malleable and ductile than steel. This property makes aluminum easier to form and bend, particularly for applications that demand intricate shapes. Steel, while strong, may require more force during bending processes due to its comparatively less malleable nature. The strength-to-weight ratio is a critical consideration. While steel is generally stronger, aluminum boasts a higher strength-to-weight ratio, making it ideal for scenarios where minimizing weight without compromising strength is paramount. This is particularly crucial in applications such as aerospace, where lightweight materials are essential for fuel efficiency.

DIRECT SHIPPING: Straight from us to You OR the JOBSITE!

Moreover, heat conductivity is a differentiating factor. Aluminum exhibits superior heat conductivity compared to steel, making it an excellent choice in applications requiring effective heat dissipation, such as electronic components and heat exchangers. Cost is a variable that influences material selection. While aluminum tends to be more expensive than steel in general, the overall cost comparison is nuanced and depends on factors such as project requirements, volume, and specific alloy grades.

In conclusion, both aluminum and steel offer unique advantages and considerations in bending and cutting processes. The selection between the two is nuanced and depends on specific project requirements, including weight considerations, corrosion resistance, heat conductivity, and cost. Manufacturers carefully evaluate these factors to make informed decisions that align with their intended applications and industry standards.

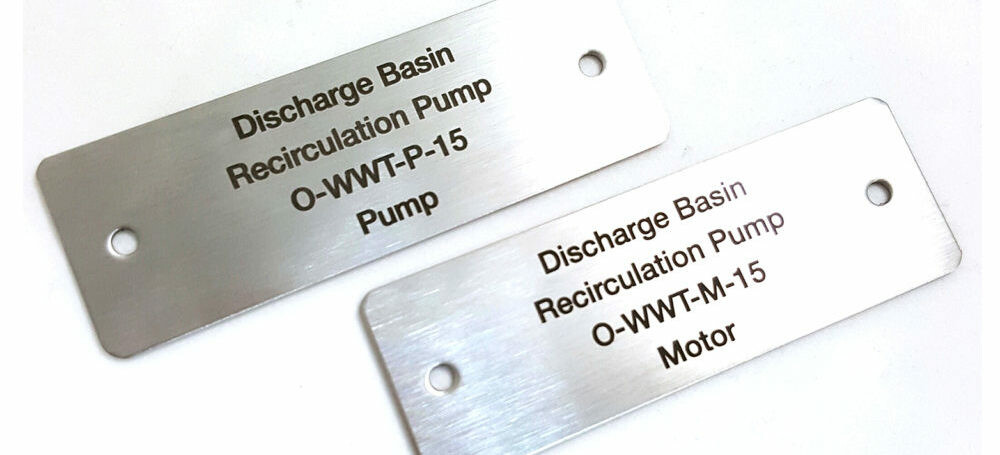

Choosing custom metal signs materials and checking their benefits

Custom metal signs are usually picked by people who want unique pieces for their projects, whether in their house, business, or anywhere else. Metal signs can endure adverse weather conditions as they are a robust and resistant material. However, certain metals can rust when exposed to moisture. But you can avoid this using aluminum, or steel, for example (often one of the best options). We can customize your metal signs in any way you desire. Executing your ideas drives us to keep on being the Laser Cutting Pros! Because it is lightweight, helping in transportation, aluminum is used a lot for outdoor custom metal signs. Another plus is the possibility to cut it into many different shapes. That is also what makes them so popular for customized signs. Aluminum signs with coatings also are fade-resistant and easy to install. For instance, you can drill holes into aluminum for mounting.

Durability

Aluminum is highly used for street signs, this is because they don’t have to replace it as often as other materials. Several outdoor signs end up fading due to exposure to UV rays over time. But when it comes to aluminum signs, the coating applied to them can expand their lifespan. They are also water and rust-resistant. And although aluminum is a tricky material, we can handle aluminum custom metal signs just fine! You can also pick steel signs to make your custom metal signs. They are strong materials. However, it is essential to handle them carefully. When installing, you need to reinforce this kind of material. Don’t forget that steel can get rusty. So, additional treatments to help avoid rust are necessary in some cases. But we are ready to offer you the best quality steel if you don’t have yours yet.

Versatility

Custom metal signs are also versatile options, allowing you to choose from a wide range of designs and concepts. You can pick a different color and have different finishes. You can also select the thickness of the material and the kind of letter you wish to engrave. For example, you can cut aluminum into any shape you can imagine. And we will laser-cut and laser-engrave according to your needs! Do you want more? Well, metal signs can have light (lightsaber style)!

So your custom metal sign can be visible at night by including lights on it. The custom possibilities are many, and we can help you achieve your goals with precision. Small, medium, big, huge, whatever the size, you can personalize custom metal signs! Our experts are set to guide you in your decision-making process. The bottom line is: you can have custom metal signs with the best. We are the Laser Cutting Pros, and all we want is to attend to your needs and expectations.If you need your parts laser engraved – we can certainly help with that as well!

Got a Project?

Fill Out This Quick RFQ Form

– OR –

Email Us Directly!

800-482-1553

Monday – Friday :: 9am – 5pm EST

Laser Fabrication:

Laser.us

LaserEngravingPros.com

LaserCuttingPros.net

EngravedSwitchplatesNOW.com

MetalTagMaker.com