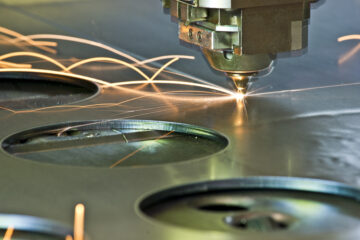

LASER CUTTING COPPER

Copper is quite a difficult material to handle and deal with when it comes to laser cutting. This is mainly because of two things. Copper beam is highly reflective and conductive. However, regardless of these, our laser experts laser cut copper according to your particular needs and requirements.

WHY CHOOSE US FOR YOUR LASER CUTTING OF COPPER?

We provide extremely precise copper laser cutting end products to our customer because we have invested in a variety of laser machines that ranges in size. Our team of experts does both engraving and laser cutting, and are also set to work on your vision to the best of their abilities in order to provide you the kind of products which you particularly envisioned.

When working with us, you are actually working with laser cutting pros who have quite an eye for creativity and innovation for your laser cutting copper projects. We also cater to special requests and work with tight deadlines, so you have nothing to worry about with you laser cutting copper projects. Our clients range from individuals to large businesses, therefore, our orders also include both big and small orders. However, you can be assured that your laser cutting copper projects will be handled by trained professionals who are very much experienced in their crafts.

How does laser cutting copper work?

First, to start the process of metal fabrication with lasers, we put a design on a computer program. Later the computer will move the laser on the material that needs to be cut. It is possible to choose a continuous wave beam or pulsed beam during the cutting process. Our light beams are set to cut any metal that a laser can cut and that you desire. A pulsed beam provides the laser with fast bursts, while a continuous wave beam runs in constant succession. Usually, it is possible to control the heat output, length, and also intensity of the laser beam. All options are customizable according to the needs of the material that is being cut by our light beams! After the laser burst, melt or vaporize the metal, we can achieve the desired shape you want. Our machines used in the metal fabrication with lasers process have high-end technology that can cut several types of metals. For example, we can laser-cut stainless steel, aluminum, and carbon steel. And our clients are from a different range of industries like:

Preciseness – Aka Precision or Precision-ness

So, the preciseness of the laser metal cutter can provide minimal area affected by the heat . You might think this could make the production slower for your laser cutting copper projects. However, it is quite the opposite. We can move our machines from one metal to another easily. Our machinery can even cut various thicknesses by programming that for a specific pace. All this saves time in the fabrication process for the laser cutting copper. Since most of the time, we must follow a strict timeline and budget, considering the most efficient method for cutting is crucial. And that is laser-cutting with the laser pros! Mistakes can cost materials. Also, investing in complex programming can add extra time to job order, and in the end, make it more expensive. That’s why the efficiency in handling time, quantity, and variety of materials you can work with are advantages highlighted in this method.

If you have special requests, you should bring them on and we’ll do a great job for you! Don’t bother if you don’t have an image in mind. ItWe can present you different ideas and you pick the best that you like. If you need your parts laser engraved – we can certainly help with that as well!

Got a Project?

Fill Out This Quick RFQ Form

– OR –

Email Us Directly!

800-482-1553

Monday – Friday :: 9am – 5pm EST

Check Out Our Sister Sites:

Laser.us

LaserEngravingPros.com

LaserCuttingPros.net

EngravedSwitchplatesNOW.com

MetalTagMaker.com