LASER CUTTING STAINLESS STEEL

If you are looking to create permanent, deep-etched, engraved, laser cut and attractive signage, laser cutting stainless steel is the best option. If you have a particular type of stainless steel signage in mind, our creative and talented experts are available to do a great job at delivering you the final end product just how you want it to be. As a matter of fact, even if you don’t have an image in mind, you can trust our team to do a job better than your expectations.

The Main Benefits of Laser Cutting Stainless Steel

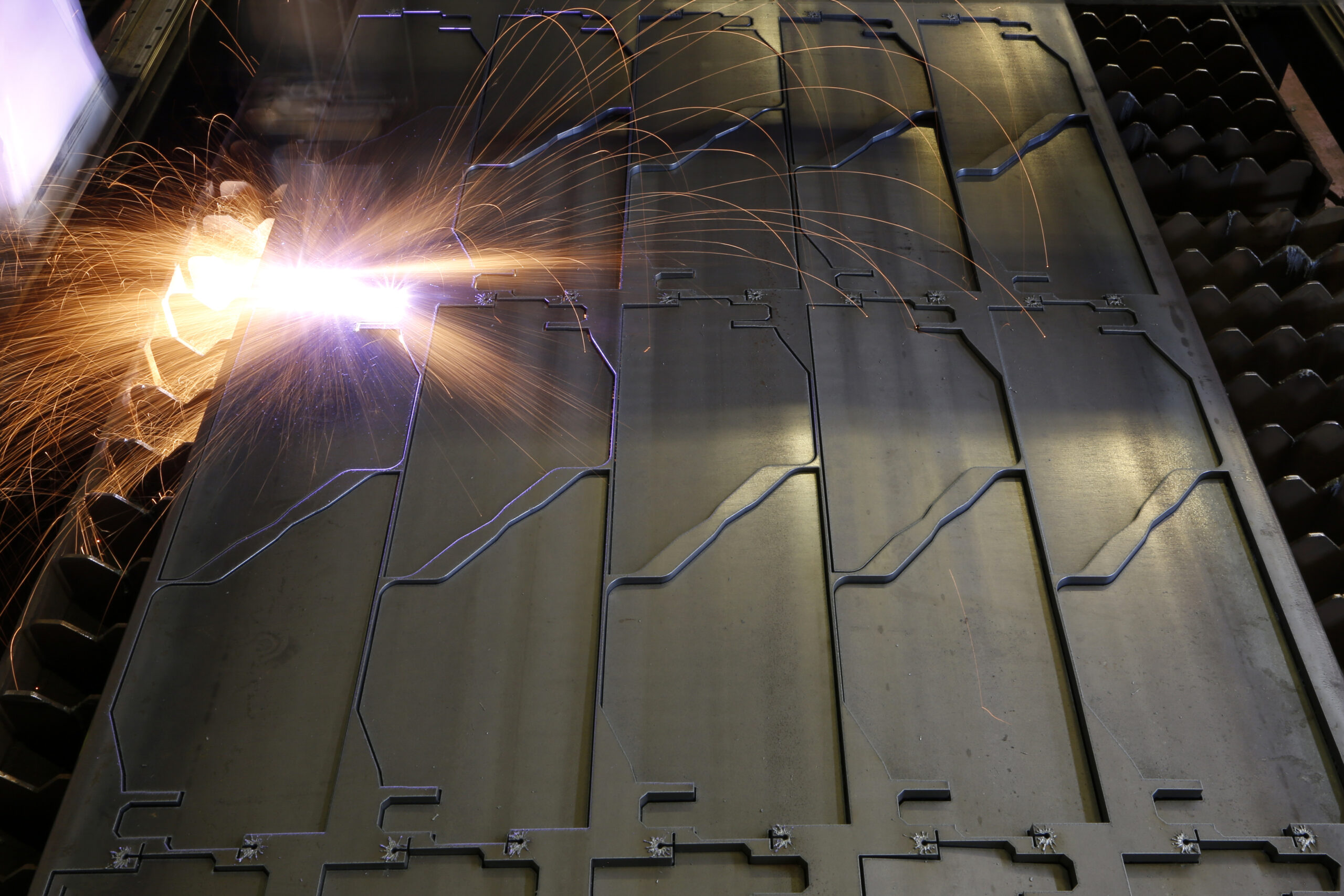

Certainly, lasers are not the only thing that cut through stainless steel. So, why use them as opposed to any other method? Well, lasers are excellent because they cut or engrave without much damage to the surrounding area, including stainless steel parts. Thus, a laser cutter is more accurate and can draw complicated shapes. If you are looking for accurate cuts, you should go with the laser cut stainless steel. Moreover, the chances of warping the material being cut are much smaller since lasers don’t use blunt force. Furthermore, since stainless steel is an excellent material for laser cutting, you can enjoy the benefits of laser cutting stainless steel, like:

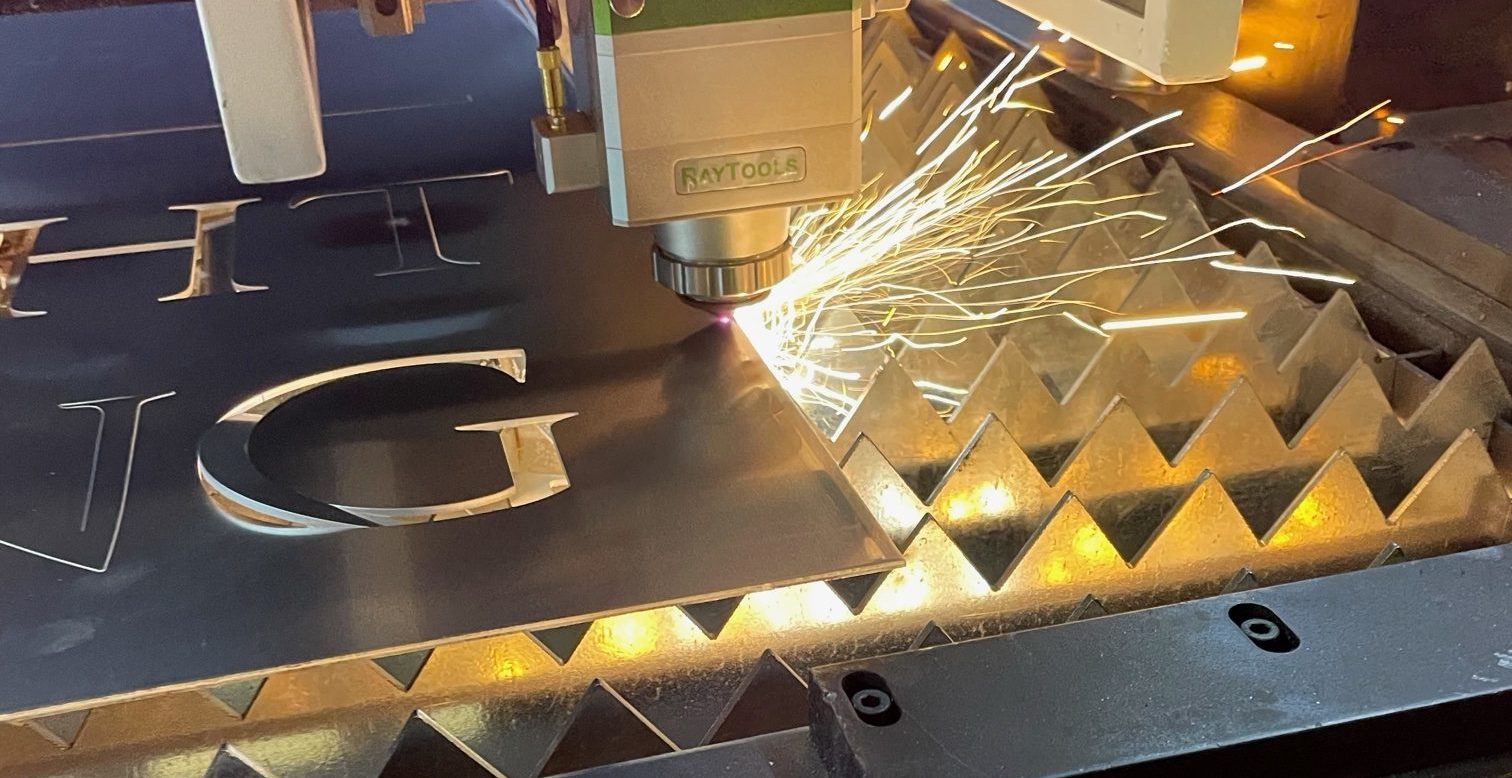

How Does Laser Cutting Stainless Steel Work?

Once a beam of light is generated inside the laser-cutting machine, partial mirrors will reflect it internally until the beam of light acquires enough energy to escape. This is the first step to laser cut stainless steel. After it escapes, the mirrors or fiber optics will conduct the light beams until they reach the lens that will focus on a small area. The machine will have a system for controlling motion built into it, allowing us to choose formats to cut or engrave according to your exact needs. If you want to laser-cut stainless steel parts precisely and have your needs and expectations attended, we are here to help you out! We are the Laser Cutting Pros with over 130 years of experience on the market, and we have the utter goal to provide you with the best laser-cutting services! If you have a project and don’t know where to start, get in touch with us right now so that our team of experts can help you take your idea out of your head and put it into action!

WHY CHOOSE US FOR YOUR LASER CUTTING STAINLESS STEEL?

We can engrave on virtually any surface using the different sized laser machines that we have acquired over the years. But, laser cutting stainless steel takes the lead here because of how much and how easy it is. Needless to say that laser cutting, etching, and engraving is our passion, and we love to play with laser beams! We do cater to special requests and deadlines because our customers are our beloved and valued community members with whom we aim to build lasting relationships. We work with individual requests as well as those by larger businesses. When you choose deep etching and laser cut stainless steel with us, be fully assured that the work will be done by trained professionals who are experienced in craft.

Once we have your precise requirements and the raw materials, we will begin working on them. We are as eager to finish an order and deliver it as are you to receive it. So, reach out to us today, and we can assure you that you will be super pleased with the end result.If you need your parts laser engraved – we can certainly help with that as well!

Got a Project?

Fill Out This Quick RFQ Form

– OR –

800-482-1553

Monday – Friday :: 9am – 5pm EST

Check Out Our Sister Sites:

Laser.us

LaserEngravingPros.com

LaserCuttingPros.net

EngravedSwitchplatesNOW.com

MetalTagMaker.com